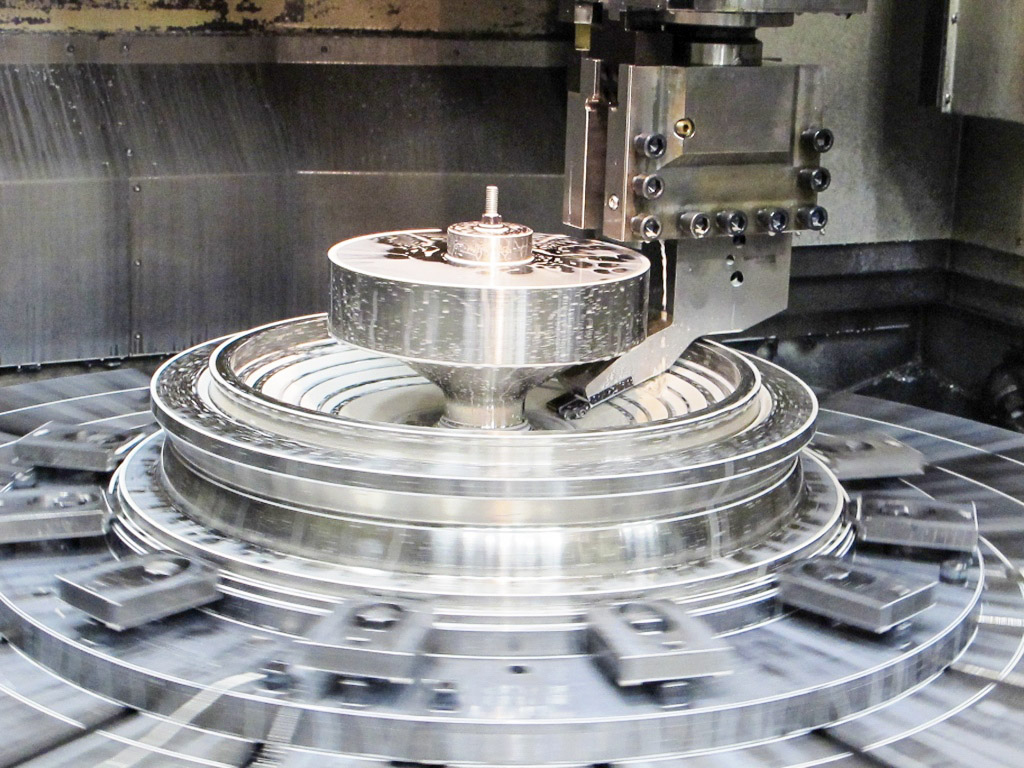

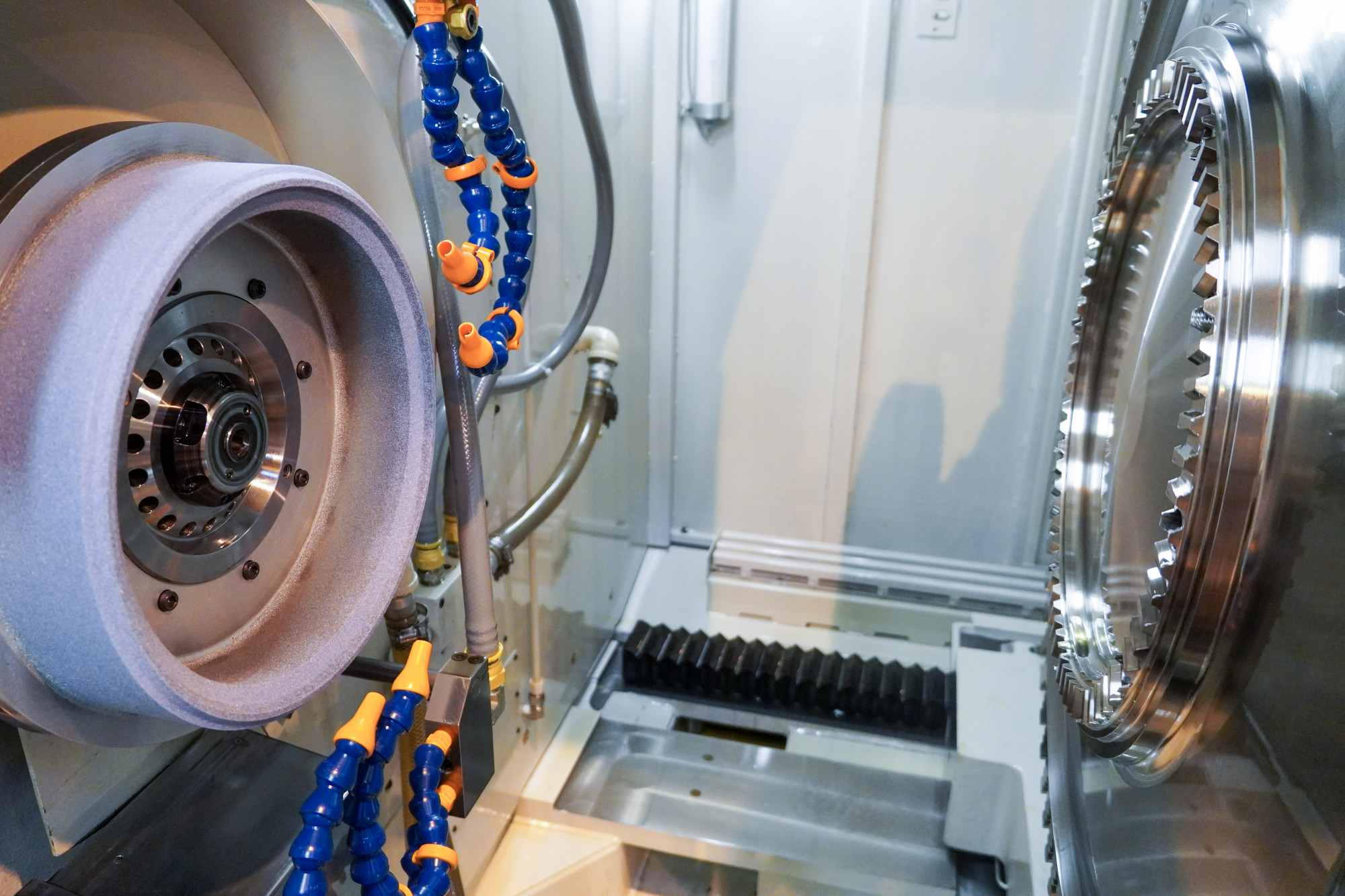

Our Customer, a leader in the automotive industry searched for over two years for a supplier that could grind micron-close tolerances to support their continuously variable transmission project.

In addition to holding such tight tolerances across TWO shafts (primary & secondary) Metalex had to have production up and running within 120 days in order to support the Customer's assembly schedule and avoid costly delays. Metalex partnered with our Customer and United Grinding Technologies to design a four machine production cell consisting of one small lathe, two Studer cylindrical grinders and a Jung ball grinder, in a temperature controlled environment. The order was placed in November, the machines were expedited from Germany, arriving in December, and by early February Metalex began shipping production parts for use in the CVT transmission. Within a few weeks, Metalex was running two shifts (20 hours per day total) and producing over 200 shafts a day.

.jpeg)

.jpg)

_-_Copy.jpg)

.jpg)

.jpg)

.jpg)

.jpg)