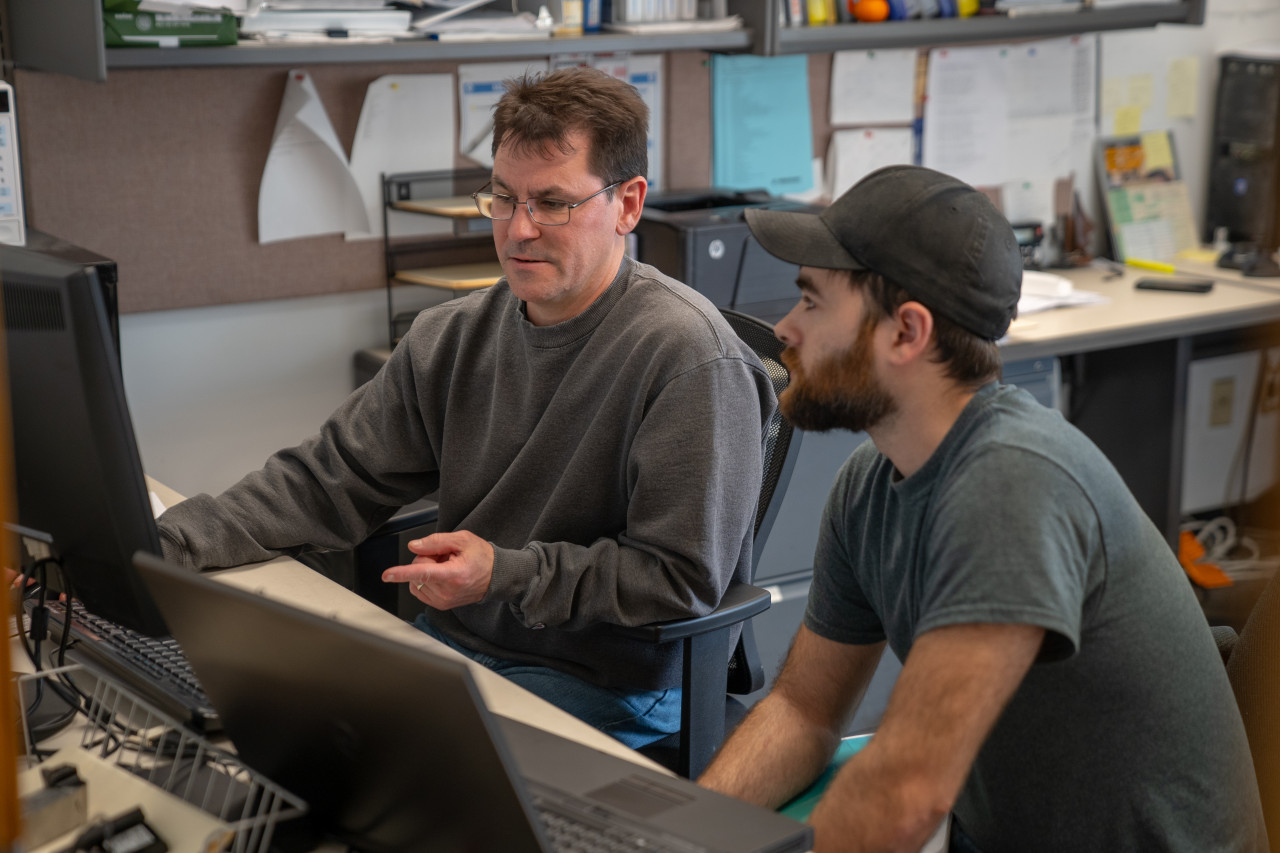

Programming

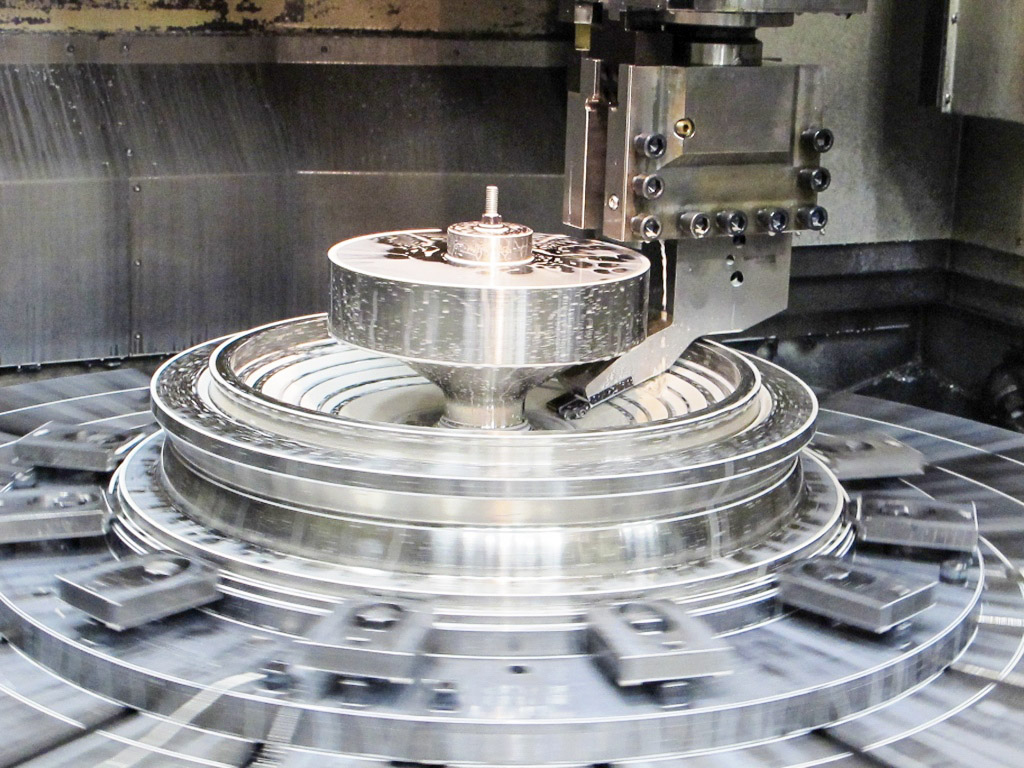

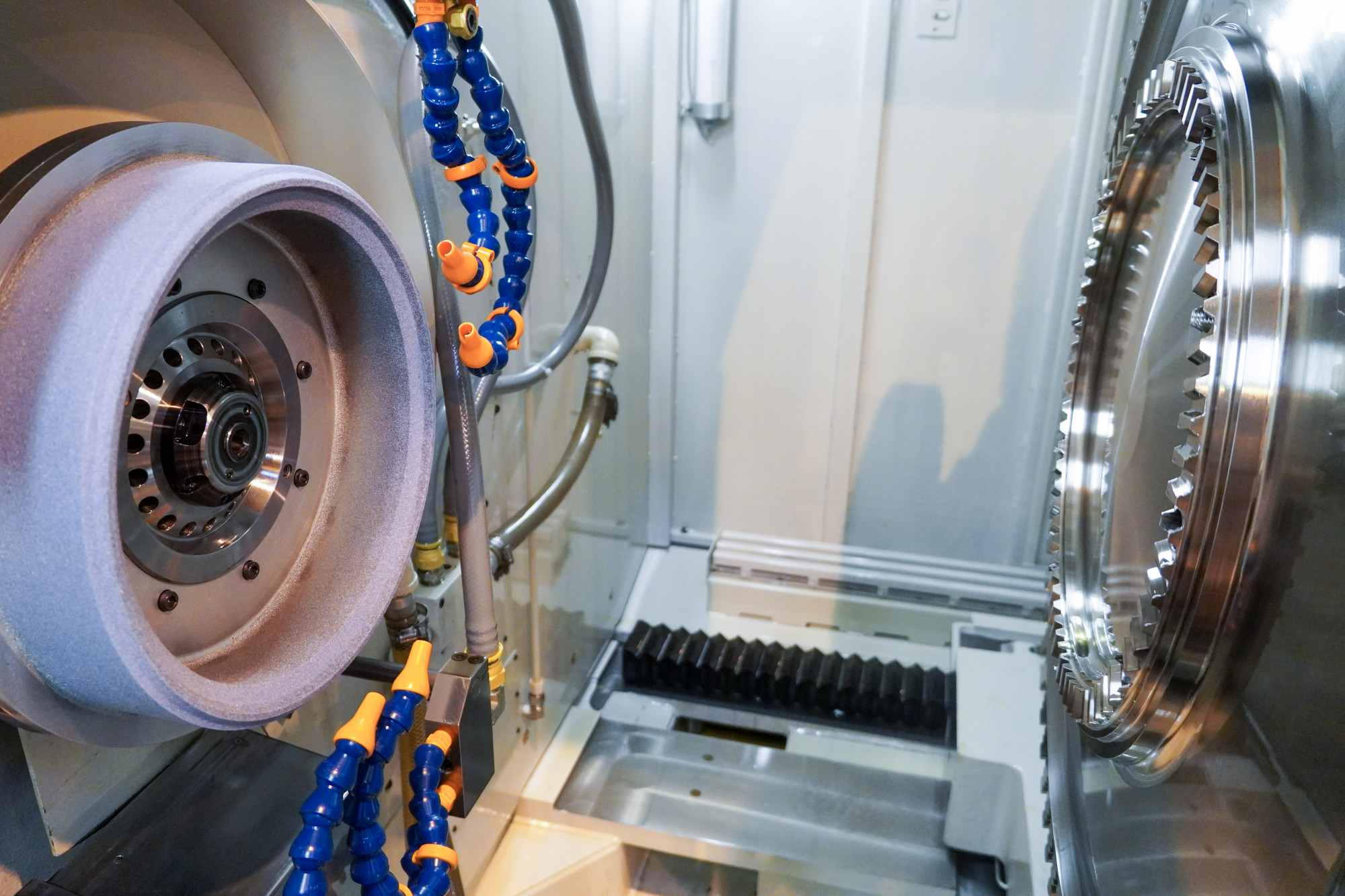

The Metalex programming team serves as the hands-on technology integrator for manufacturing operations across the company. Through close collaboration with our talented team of 5-axis machinists, tool makers, designers, engineers and inspectors, our programmers generate truly innovative machining strategies using the latest CAM software to develop CNC programs that drive our multi-axis machines with the efficiency and precision needed to successfully produce some of the most complex prototypes and production components for the aerospace, space, energy and consumer products industries.

Acting as a liaison between Metalex technical community and shop floor, the programming team’s enthusiasm and leadership serve as a catalyst to promote and implement best practices, reduce risk, apply the latest technology and share knowledge throughout Metalex. Our programmers also support customers during the quotation process, analyzing customer part designs for manufacturability and providing recommendations to improve affordability, throughput time and quality of parts.

The Metalex programming team utilizes a wide range of software packages to do its work, including Siemens NX, CATIA, Creo (formerly Pro/ENGINEER), Applicon, CAMAX, AutoCAD, PC-DMIS and more. In addition, we make CAD data transfer as easy as possible for our customers by accepting Parasolid, IGES, STEP and/or DFX file formats.

.jpg)

In my mind, Metalex represents a unique combination of state of the art programming and machining technology and world class craftsmanship. Your company is an extremely valuable asset to the U.S. Space program and Aerospace industry. Pratt & Whitney relies on Metalex to produce some of the most complex and critical components in our rocket engines and you do a superb job. When I think of Metalex, I look forward to a long-term relationship between our companies, this is a partnership that will help get us back to the moon, mars and beyond.

.jpeg)

.jpg)

.jpg)