Inspection

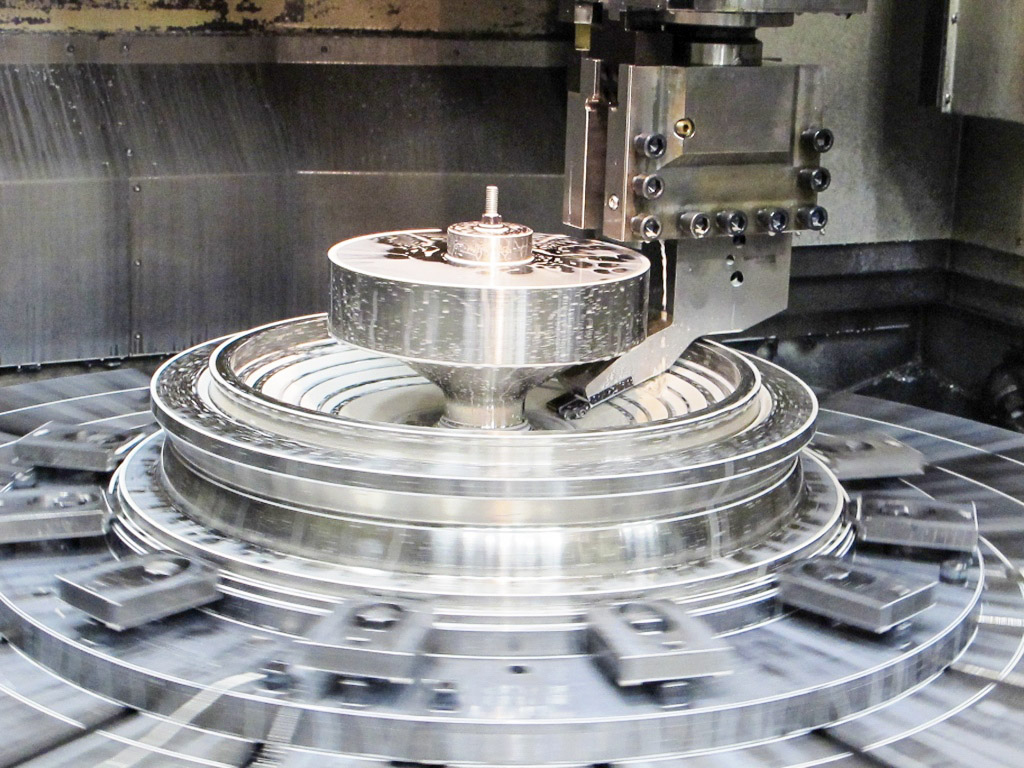

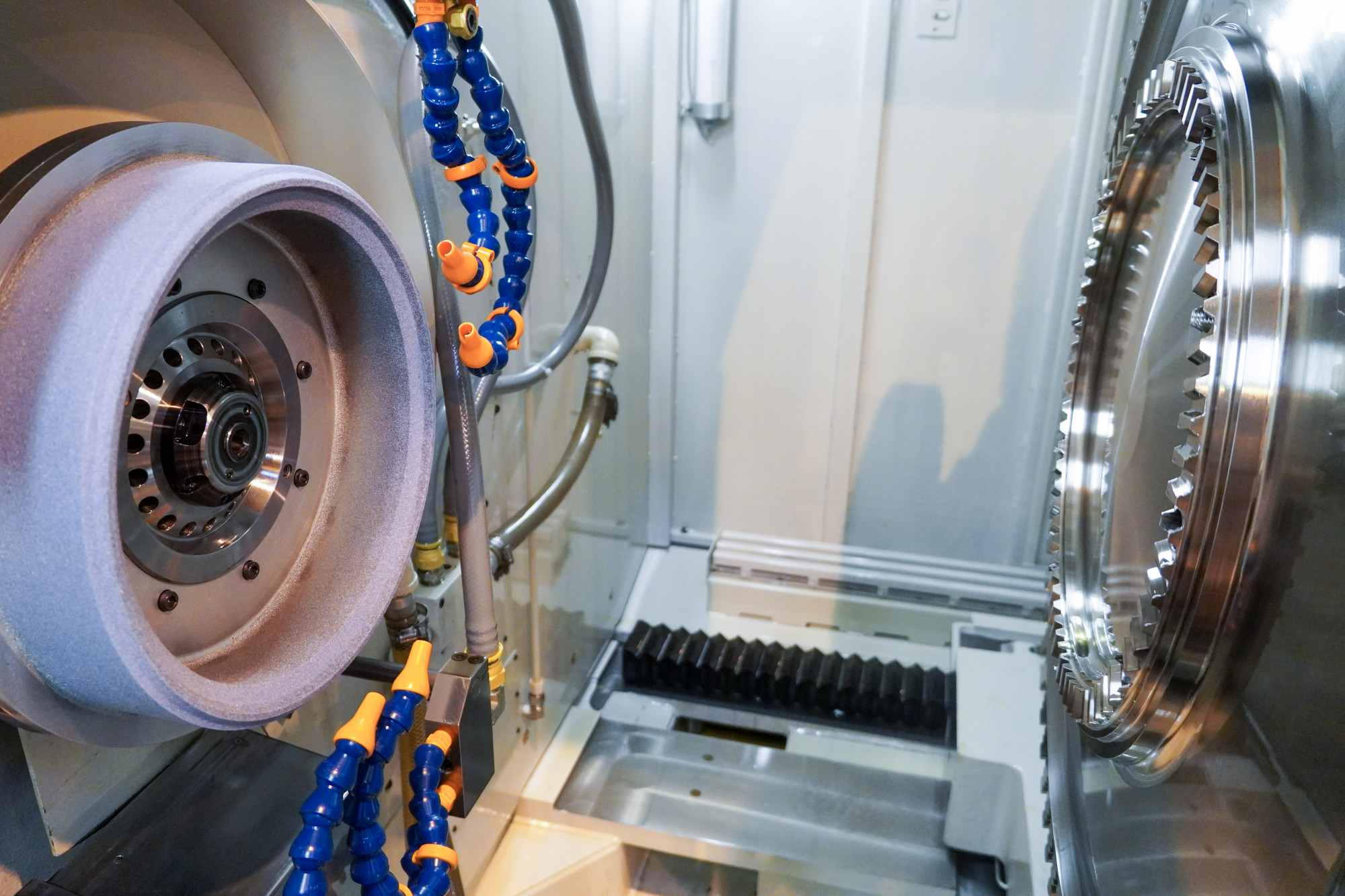

At Metalex, the complex and challenging nature of our work requires that precision is part of our manufacturing processes from their inception. On difficult parts and assemblies, our programming, engineering, machining and quality teams work together during the start-up, development and prove-out of the manufacturing process.

When a new part is released, the quality and engineering team assume ownership of the first article and follows it throughout the manufacturing cycle, from ensuring that the fixturing design supports both machining and inspection to calling a small team meeting to collaborate on developing the most efficient and consistent manufacturing process required, all to deliver excellent quality for the first part and any future production runs.

Inspection Equipment

At every stage of this process, we create inspection programs from CAD data in real time with PC-DMIS software using five advanced coordinate-measuring machines (CMM) for final inspection, portable FaroArm units for in-process inspections and a laser tracker for larger components , all to ensure we’re reaching our quality goals and meeting your specifications.

Calibration

Our calibration system, which meets ISO 10012-1 standards, tracks over 2,200 inspection instruments located throughout the shop. As a result, Metalex is able to offer the highest level of quality at competitive costs for the first-article part as well as all future production runs.

Quality is our only Business. We have no other options. Every time we fly a mission, we risk everything. Metalex has our business because the quality and consistency are there.

Check out these related projects that we have successfully partnered with our customers on.

.jpeg)

.jpg)

.jpg)

.jpg)