Activity Based Costing

A Culture of Activity Based Costing from the Beginning

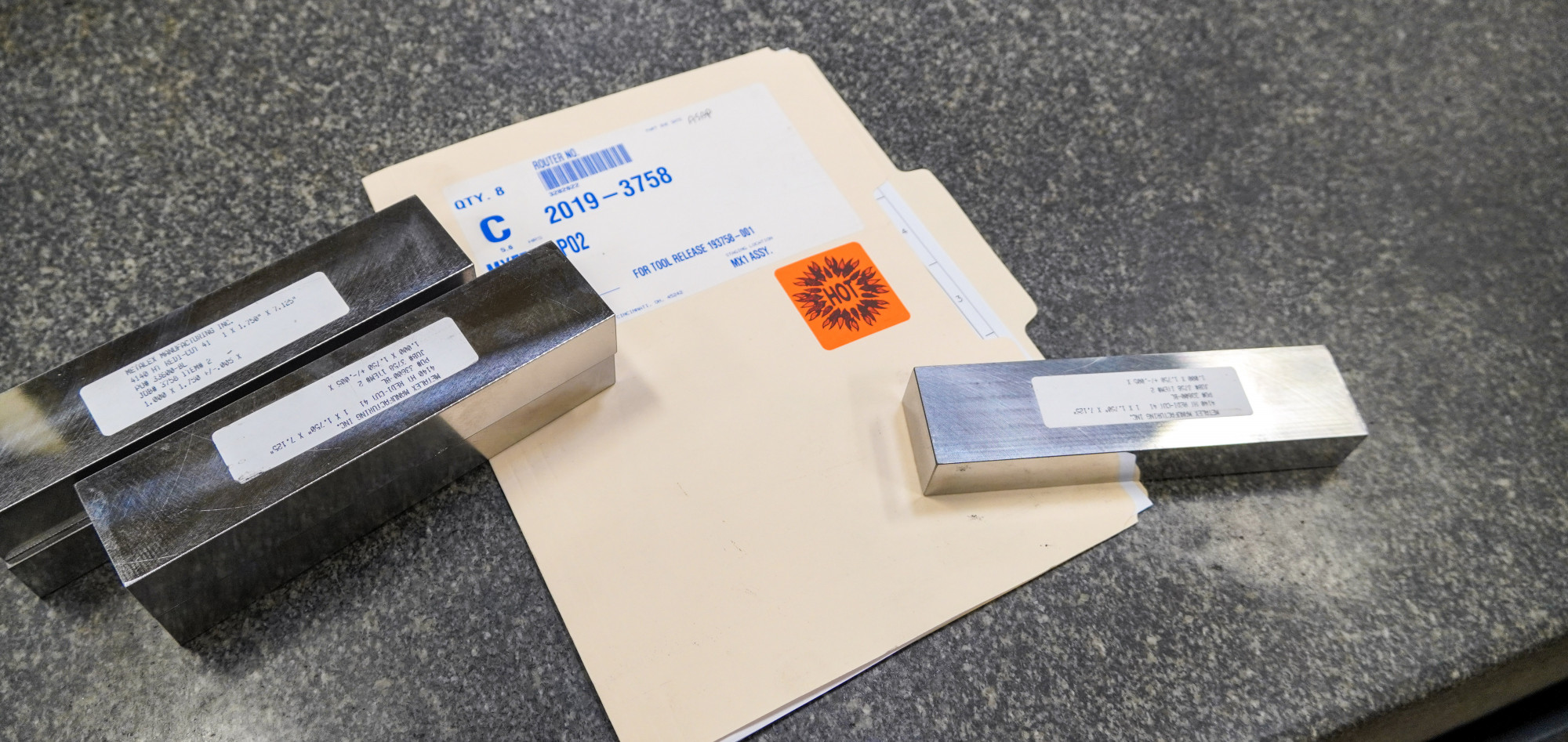

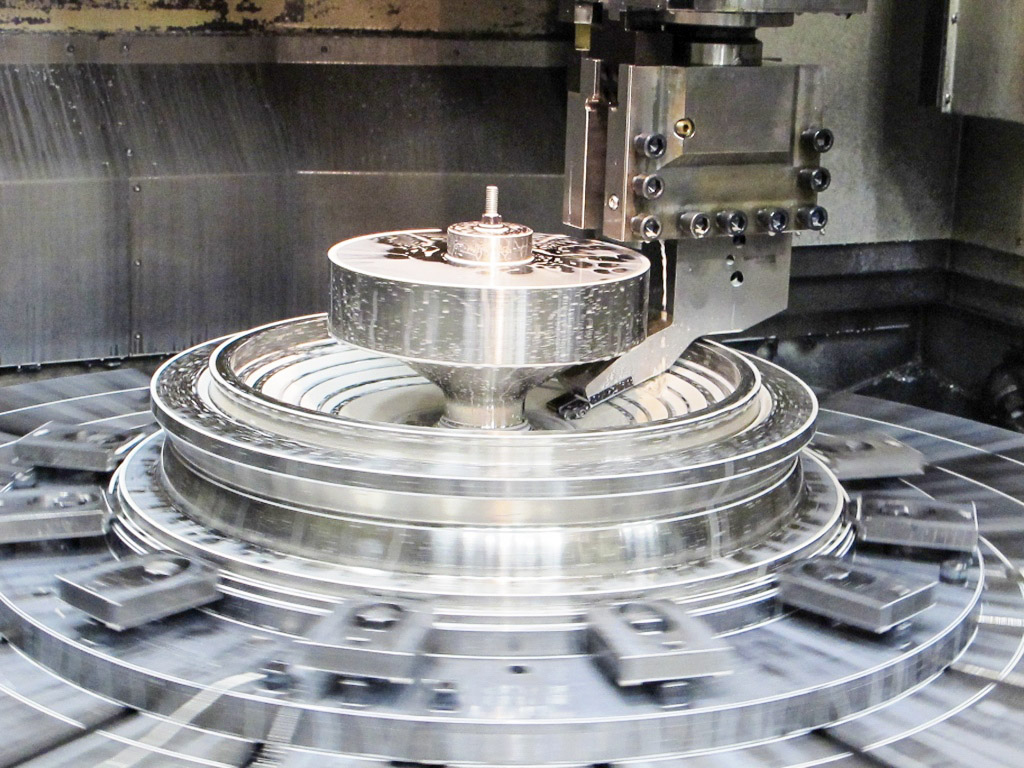

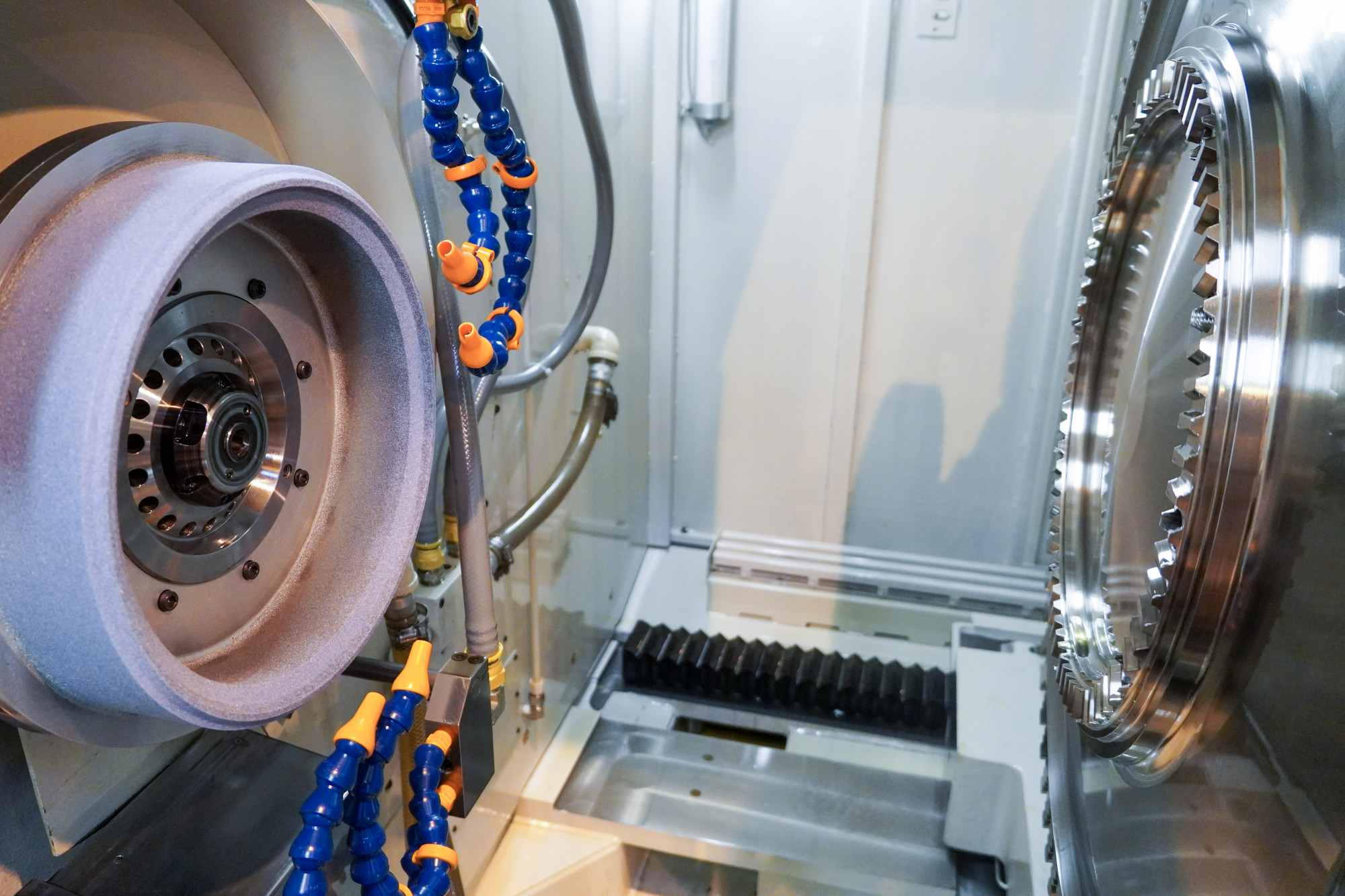

Since we opened for business, Metalex has used Activity Based Costing to ensure we are an efficient, cost-conscious and accountable company. Our system is designed so Customer's pay only for the technology, expertise and services required to complete their projects. By continuously using actual performance data as a tool to identify best practices, benchmark performance and opportunities for improvement, Metalex is committed to ensuring our customers receive excellent quality at the best possible value.

How Metalex Activity Based Costing Works for our Customers

All Metalex, Teammates record their daily effort in real time and in detail including job number and activity code to accurately describe the Task taking place. Every day, the labor entered into our database is verified by the independent Kronos system, by comparing actual hours worked with recorded time, ensuring time allocated to each job is accurate. This detailed reporting system allows Metalex to monitor quoted vs actual performance at job or operation level, during any point in the manufacturing process and immediately identify, correct and eliminate disconnects before they impact our customers quality, cost or on-time delivery. In addition to disconnects, our system identifies benchmark performance. When a Metalex Teammate completes an operation, if the actual hours are lower than the planned times, the system will set a benchmark that all teammates will be expected to reach in the future.

How Using Actual Activity Data Supports Accuracy In Our Quotation Process

Metalex’ Activity Based Costing system is the foundation for our quotation process. For repeat Jobs or similar parts, Metalex uses actual historical benchmark data to estimate cost. This process ensures that Metalex estimates are based on our best performance, not a historical average of mediocre or less competitive performances on the same or similar part or Job. For first time prototype development jobs, all labor and cost estimates included in the quotation, including Non Recurring efforts, are used throughout the entire manufacturing process as a guide and performance indicator.

Using The Interaction Without Boundaries Process To Achieve Affordability For All Of Our Customers

The Interaction Without Boundaries process gives every Teammate the opportunity to identify and correct significant disconnects between estimated vs. actual hours in an environment where all Teammates are accountable and no Teammate stands alone. It is also an expectation, and a part of our culture, that Activity Based Costing helps us to communicate disconnects with processes, either within a single team or even across different teams. When a significant disconnect is identified at any point in the manufacturing process, Leaders organize a Small Team Meeting in real time with all the required teammates, and publish the Summary and Action Items. Comparison of the quote cost vs actual cost vs projected cost is the responsibility of Business Operations. Communication of accurate and timely data combined with a culture of correcting issues with pace and communicating learning's all drive Affordability.

Using this simple process to keep the scoreboard visible for all to see and constantly challenging Teammates, Cells, and Areas to perform at their very best, Metalex ensures lasting value for our customers. At the same time, we provide our Teammates with the opportunity to be the best they can be and elevate their marketability status.

.jpeg)

.jpg)