FAQ

How Can We Help You ?

You ask. We answer.

First Off, thank you for visiting our website and for your interest in our company. Below we have outlined Frequently Asked Questions but if do not answer your question, we encourage you to contact us and we will be happy to answer any additional questions.

GENERAL QUESTIONS

Metalex is registered as a defense supplier with the United States Department of State, Office of Defense Trade Controls (PM/DTC Registration Number is 100314131). Our Company’s technology transfer control plan is approved by the U.S. Department of Defense, Office of the Defense Threat Reduction Agency.

Metalex is ISO 9001 and AS9100 Certified and NADCAP accredited for welding and nonconventional machining. In addition, Metalex is a registered Defense Supplier with the United States Department of State, PM/DTC Registration Number is 100314131.

All Metalex, Teammates record their daily effort in real time and in detail including job number and activity code to accurately describe the Task taking place. Every day, the labor entered into our database is verified by the independent Kronos system, by comparing actual hours worked with recorded time, ensuring time allocated to each job is accurate. This detailed reporting system allows Metalex to monitor quoted vs actual performance at job or operation level, during any point in the manufacturing process and immediately identify and eliminate disconnects before they impact our customers quality, cost or on-time delivery. In addition to disconnects, our system identifies benchmark performance. When a Metalex Teammate completes an operation, if the actual hours are lower than the planned times, the system will set a benchmark that all teammates will be expected to reach in the future.

Successful companies have a clear mental picture of how their organization looks when operating at its absolute best. At Metalex, this vision is defined within our business plan, Interactions Without Boundaries or “IWB”. The IWB plan is documented in what we call our “Playbook” – a manual for every Metalex teammate and leader, clearly defining their specific role and responsibilities with an emphasis on communicating expectations between and among Metalex teammates to ensure the total team performs at its best each day.

Metalex is a privately held, veteran owned U.S. firm located in the greater Cincinnati, Ohio area, which has a rich history of machining expertise and exceptional craftsmen. Founded in 1971, Metalex has grown to be one of America’s leading high tech manufacturing companies servicing global leaders in the Aerospace and Defense, Consumer Goods, Energy Sciences, Power Generation, Nuclear, Space and Naval industries.

At Metalex, we emphasize a culture of continuous improvement, transparency, accountability and openness, which is why implementing industry 4.0 has been such a natural evolution that has been readily adopted by our workforce at every level of our organization to help us work smarter to ensure we meet our customer's needs. Contact us to learn more about our digital journey.

Forward Vision – Investing in Tomorrow - From the beginning, Metalex’s approach to business has been aimed toward providing our customers with a one-stop shop for the latest in manufacturing technology and support from a team of the most talented professionals in the industry. To ensure continuous improvement toward that goal, we aggressively invest in the future with advanced machining systems, shared learning resources and a company structure that enables self-directed team members to contribute to the business’s long-term success. Our ability to provide innovative manufacturing services with unique capabilities makes Metalex the partner of choice across a wide range of industrial segments, and we stand ready to use our talents to help our customers achieve competitive excellence and ongoing business growth.

Our work environment is specifically designed to encourage personal, professional and company growth. As a technology company, Metalex offers unique growth and advancement opportunities, and all of our employees receive extensive, multidisciplinary training that supports the ever-changing needs of our customers and elevates their personal marketability.

Contract manufacturing lets you access specialized facilities, equipment, expertise and infrastructure needed to complete your project with having to make a major capital and time investment to required to develop these resources. If you’re looking to scale up production or need state-of-the-art processes, a contract manufacturing partner is a great way to ensure quality, on-time delivery and reliability.

Beyond that, a highly qualified partner that has specific expertise that have been acquired through years of developing and manufacturing highly complex components and assemblies . That experience can help you avoid or quickly solve challenges that would otherwise increase costs and affect time to market.

The Images posted on this website are licensed for private, non-commercial use only.If you intend to use Metalex-owened photos for commercial use, you must receive Metalex' express written approval before use of any image on this website.

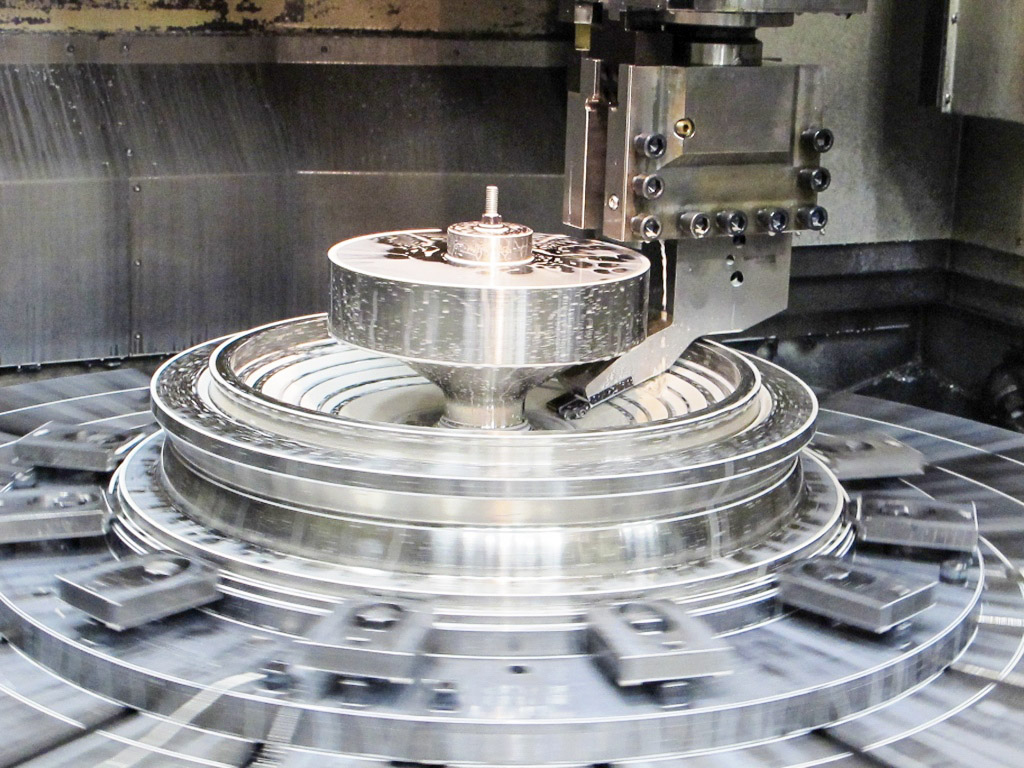

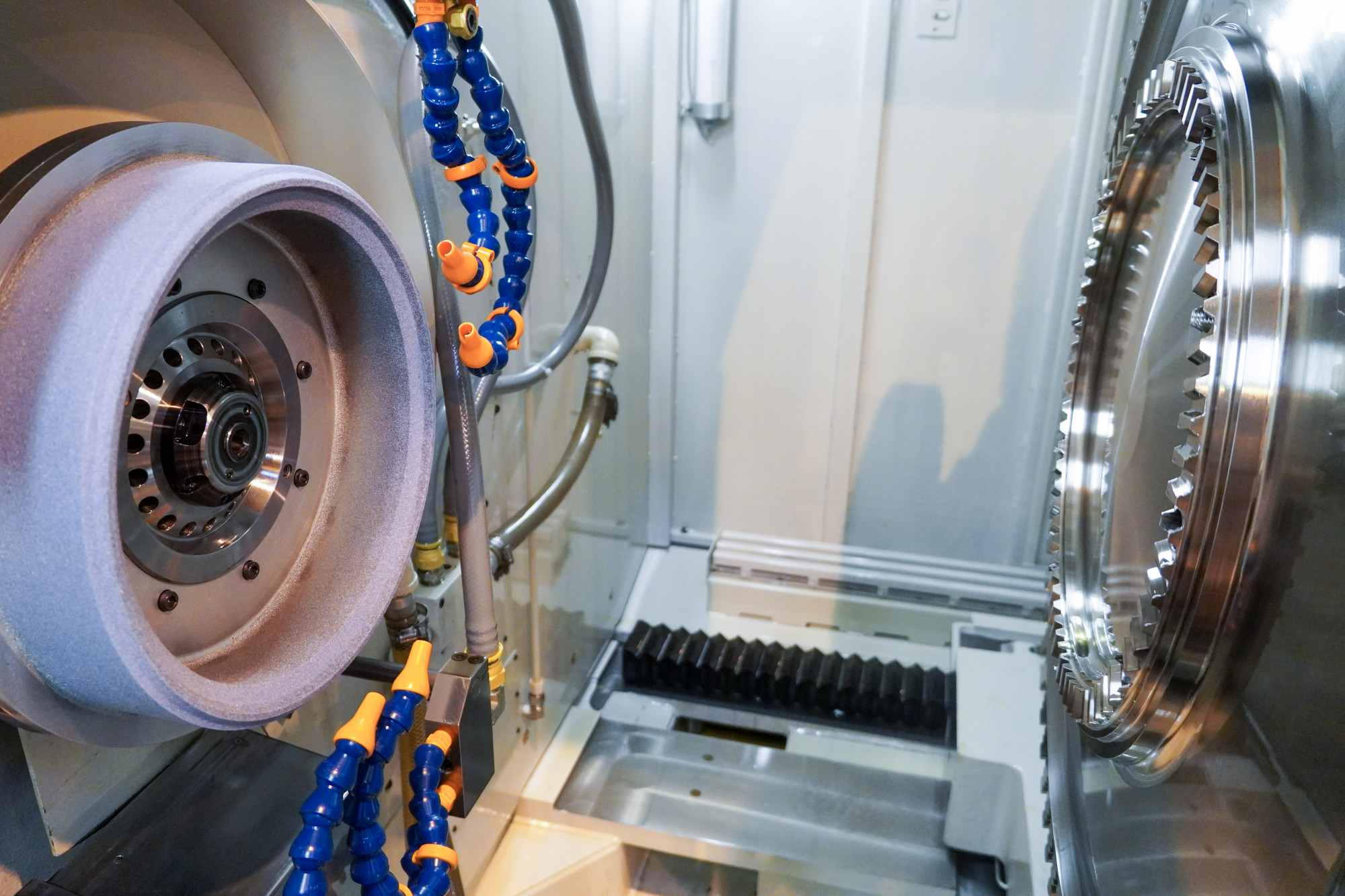

Protecting Our Customer's Intellectual Property - At Metalex, protecting our Customer's intellectual property is something we take very seriously for all of our customers. Due to the highly competitive nature of the markets and products we support, when appropriate as a precautionary measure to protect our customers intellectual property, Metalex has made the decision to only included adobe stock images that are representative of the type of components we manufacture. In other cases, Metalex has included our own images of parts that are acceptable to be in the public domain.

Doing Business with Metalex - Supplier Information: Companies or individuals interested in doing business with Metalex should contact our Purchasing group directly. Please submit information on our website using a general information inquiry form. (CTA - https://met0618-01-18.71.reusser.design/contact-us)

Metalex Name and Logo: Use of the Metalex signature, Metalex trademarks and trade names, and other elements of the Metalex corporate identity must be approved in writing by an authorized member of Metalex Management team.

SERVICES

At Metalex, we emphasize a culture of continuous improvement, transparency, accountability and openness, which is why implementing industry 4.0 has been such a natural evolution that has been readily adopted by our workforce at every level of our organization to help us work smarter to ensure we meet our customer's needs. Contact us to learn more about our digital journey.

Doing Business with Metalex - Supplier Information: Companies or individuals interested in doing business with Metalex should contact our Purchasing group directly. Please submit information on our website using a general information inquiry form. (CTA - https://met0618-01-18.71.reusser.design/contact-us)

Metalex is ISO 9001 and AS9100 Certified and NADCAP accredited for welding and nonconventional machining. In addition, Metalex is a registered Defense Supplier with the United States Department of State, PM/DTC Registration Number is 100314131.

Metalex' exceptional team of skilled welders are AWS, NavSea and NADCAP certified, with expertise in MIG and TIG welding of aluminum, stainless steel, bronze, titanium and other exotic alloys to meet each customer's unique weld certification requirements for aerospace, space, energy, science and marine welding applications.

Curvic Grinding is among the most challenging grinding applications performed at Metalex, because the manufacturing of Curvic couplings requires a highly specialized, unique grinding technique with extreme accuracy and hands-on expertise to successfully perform the process. Curvic couplings resemble face gears, except the teeth are curved in both the radial and axial directions. These convex and concave curvic couplings mate together to create extremely accurate interlocking assemblies designed to withstand huge amounts of force while in operation and still maintaining precise positioning of the assembly. The Curvic coupling is critical for high powered applications such as helicopters, power generation, turbochargers, machine tools, jet engines, etc.

Metalex offers a wide variety of precision manufacturing services including the following; 5-Axis Milling, Turning, Mill-Turn, Welding, Fabrication, Assembly & Testing, ID /OD Grinding, Cruvic Griding, Wire EDM, RAM EDM, CMM Inspection.

Metalex serves a diverse group of customers and markets including ; Aerospace, Space, Power Generation, Oil & Gas, Transportation, Science, Marine, Hydro, Nuclear and Consumer Goods.

Contract manufacturing lets you access specialized facilities, equipment, expertise and infrastructure needed to complete your project with having to make a major capital and time investment to required to develop these resources. If you’re looking to scale up production or need state-of-the-art processes, a contract manufacturing partner is a great way to ensure quality, on-time delivery and reliability.

Beyond that, a highly qualified partner that has specific expertise that have been acquired through years of developing and manufacturing highly complex components and assemblies . That experience can help you avoid or quickly solve challenges that would otherwise increase costs and affect time to market.

COMPANY

All Metalex, Teammates record their daily effort in real time and in detail including job number and activity code to accurately describe the Task taking place. Every day, the labor entered into our database is verified by the independent Kronos system, by comparing actual hours worked with recorded time, ensuring time allocated to each job is accurate. This detailed reporting system allows Metalex to monitor quoted vs actual performance at job or operation level, during any point in the manufacturing process and immediately identify and eliminate disconnects before they impact our customers quality, cost or on-time delivery. In addition to disconnects, our system identifies benchmark performance. When a Metalex Teammate completes an operation, if the actual hours are lower than the planned times, the system will set a benchmark that all teammates will be expected to reach in the future.

Metalex' three manufacturing facilities total more than 400,000 sq. ft. All of our facilities are located within ¼ mile of each other. Our main manufacturing operation is located at 5750 Cornell Road, Cincinnati, Ohio 45242.

The Images posted on this website are licensed for private, non-commercial use only.If you intend to use Metalex-owened photos for commercial use, you must receive Metalex' express written approval before use of any image on this website.

Protecting Our Customer's Intellectual Property - At Metalex, protecting our Customer's intellectual property is something we take very seriously for all of our customers. Due to the highly competitive nature of the markets and products we support, when appropriate as a precautionary measure to protect our customers intellectual property, Metalex has made the decision to only included adobe stock images that are representative of the type of components we manufacture. In other cases, Metalex has included our own images of parts that are acceptable to be in the public domain.

Metalex Name and Logo: Use of the Metalex signature, Metalex trademarks and trade names, and other elements of the Metalex corporate identity must be approved in writing by an authorized member of Metalex Management team.

Successful companies have a clear mental picture of how their organization looks when operating at its absolute best. At Metalex, this vision is defined within our business plan, Interactions Without Boundaries or “IWB”. The IWB plan is documented in what we call our “Playbook” – a manual for every Metalex teammate and leader, clearly defining their specific role and responsibilities with an emphasis on communicating expectations between and among Metalex teammates to ensure the total team performs at its best each day.

Forward Vision – Investing in Tomorrow - From the beginning, Metalex’s approach to business has been aimed toward providing our customers with a one-stop shop for the latest in manufacturing technology and support from a team of the most talented professionals in the industry. To ensure continuous improvement toward that goal, we aggressively invest in the future with advanced machining systems, shared learning resources and a company structure that enables self-directed team members to contribute to the business’s long-term success. Our ability to provide innovative manufacturing services with unique capabilities makes Metalex the partner of choice across a wide range of industrial segments, and we stand ready to use our talents to help our customers achieve competitive excellence and ongoing business growth.

Metalex offers a wide variety of precision manufacturing services including the following; 5-Axis Milling, Turning, Mill-Turn, Welding, Fabrication, Assembly & Testing, ID /OD Grinding, Cruvic Griding, Wire EDM, RAM EDM, CMM Inspection.

Metalex is a privately held, veteran owned U.S. firm located in the greater Cincinnati, Ohio area, which has a rich history of machining expertise and exceptional craftsmen. Founded in 1971, Metalex has grown to be one of America’s leading high tech manufacturing companies servicing global leaders in the Aerospace and Defense, Consumer Goods, Energy Sciences, Power Generation, Nuclear, Space and Naval industries.

INDUSTRIES

At Metalex, we emphasize a culture of continuous improvement, transparency, accountability and openness, which is why implementing industry 4.0 has been such a natural evolution that has been readily adopted by our workforce at every level of our organization to help us work smarter to ensure we meet our customer's needs. Contact us to learn more about our digital journey.

Metalex' exceptional team of skilled welders are AWS, NavSea and NADCAP certified, with expertise in MIG and TIG welding of aluminum, stainless steel, bronze, titanium and other exotic alloys to meet each customer's unique weld certification requirements for aerospace, space, energy, science and marine welding applications.

Metalex serves a diverse group of customers and markets including ; Aerospace, Space, Power Generation, Oil & Gas, Transportation, Science, Marine, Hydro, Nuclear and Consumer Goods.

PROJECTS

Curvic Grinding is among the most challenging grinding applications performed at Metalex, because the manufacturing of Curvic couplings requires a highly specialized, unique grinding technique with extreme accuracy and hands-on expertise to successfully perform the process. Curvic couplings resemble face gears, except the teeth are curved in both the radial and axial directions. These convex and concave curvic couplings mate together to create extremely accurate interlocking assemblies designed to withstand huge amounts of force while in operation and still maintaining precise positioning of the assembly. The Curvic coupling is critical for high powered applications such as helicopters, power generation, turbochargers, machine tools, jet engines, etc.

Contract manufacturing lets you access specialized facilities, equipment, expertise and infrastructure needed to complete your project with having to make a major capital and time investment to required to develop these resources. If you’re looking to scale up production or need state-of-the-art processes, a contract manufacturing partner is a great way to ensure quality, on-time delivery and reliability.

Beyond that, a highly qualified partner that has specific expertise that have been acquired through years of developing and manufacturing highly complex components and assemblies . That experience can help you avoid or quickly solve challenges that would otherwise increase costs and affect time to market.

WHY METALEX

Our work environment is specifically designed to encourage personal, professional and company growth. As a technology company, Metalex offers unique growth and advancement opportunities, and all of our employees receive extensive, multidisciplinary training that supports the ever-changing needs of our customers and elevates their personal marketability.

All Metalex, Teammates record their daily effort in real time and in detail including job number and activity code to accurately describe the Task taking place. Every day, the labor entered into our database is verified by the independent Kronos system, by comparing actual hours worked with recorded time, ensuring time allocated to each job is accurate. This detailed reporting system allows Metalex to monitor quoted vs actual performance at job or operation level, during any point in the manufacturing process and immediately identify and eliminate disconnects before they impact our customers quality, cost or on-time delivery. In addition to disconnects, our system identifies benchmark performance. When a Metalex Teammate completes an operation, if the actual hours are lower than the planned times, the system will set a benchmark that all teammates will be expected to reach in the future.

Successful companies have a clear mental picture of how their organization looks when operating at its absolute best. At Metalex, this vision is defined within our business plan, Interactions Without Boundaries or “IWB”. The IWB plan is documented in what we call our “Playbook” – a manual for every Metalex teammate and leader, clearly defining their specific role and responsibilities with an emphasis on communicating expectations between and among Metalex teammates to ensure the total team performs at its best each day.

CAREERS

Our work environment is specifically designed to encourage personal, professional and company growth. As a technology company, Metalex offers unique growth and advancement opportunities, and all of our employees receive extensive, multidisciplinary training that supports the ever-changing needs of our customers and elevates their personal marketability.

Successful companies have a clear mental picture of how their organization looks when operating at its absolute best. At Metalex, this vision is defined within our business plan, Interactions Without Boundaries or “IWB”. The IWB plan is documented in what we call our “Playbook” – a manual for every Metalex teammate and leader, clearly defining their specific role and responsibilities with an emphasis on communicating expectations between and among Metalex teammates to ensure the total team performs at its best each day.

.jpeg)

.jpg)