Why Metalex

With unique expertise in high precision machining, fabrication and mechanical assembly combined with an unwavering commitment to Quality, Craftsmanship and Service, Metalex has earned our reputation for excellence by embracing the most challenging, first-time projects and small lot production of high precision components at the cutting edge of manufacturing technology.

For nearly 50 years, we have been serving a diverse customer base across many industries including Aerospace, Energy, Oil & Gas, Science, Consumer Goods, Space, Marine and many more. We continuously reinvest in our technology, facilities and people to build an organization with truly unique, world-class manufacturing capability. We apply diverse technologies to support our customers on their most ambitious manufacturing projects regardless of size, from small to oversized parts and assemblies, Metalex is proud to be the one-stop, partner of choice for industry leading companies across multiple markets. Please contact us to learn more.

"The Future Waits for No One, and We Refuse to Wait for It. So, we create it. We're not just machinists and engineers, we're pioneers"

.jpg)

ENGINEERING

Metalex provides comprehensive manufacturing engineering services, which include complete design to build services for specialized machinery, equipment repair and rapid prototyping. In addition, our engineers use their wide-ranging and diverse expertise to assist Customers with product design, value and reverse engineering, project management, and advanced quality planning for change management. Metalex produces first-of-its-kind prototypes, as well as production parts, for global leaders in the aerospace, defense, space, energy and consumer goods industries. We frequently apply the critical manufacturing skills, technology and learning acquired from our work in one industry to benefit our customers across many other industries.

.jpg)

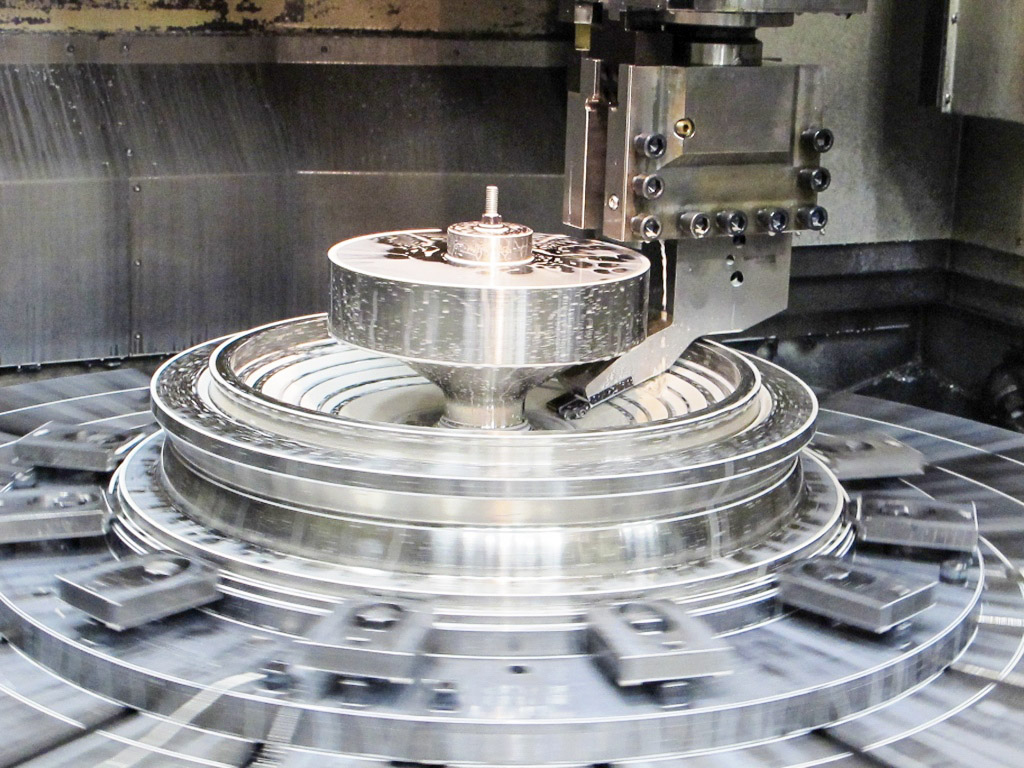

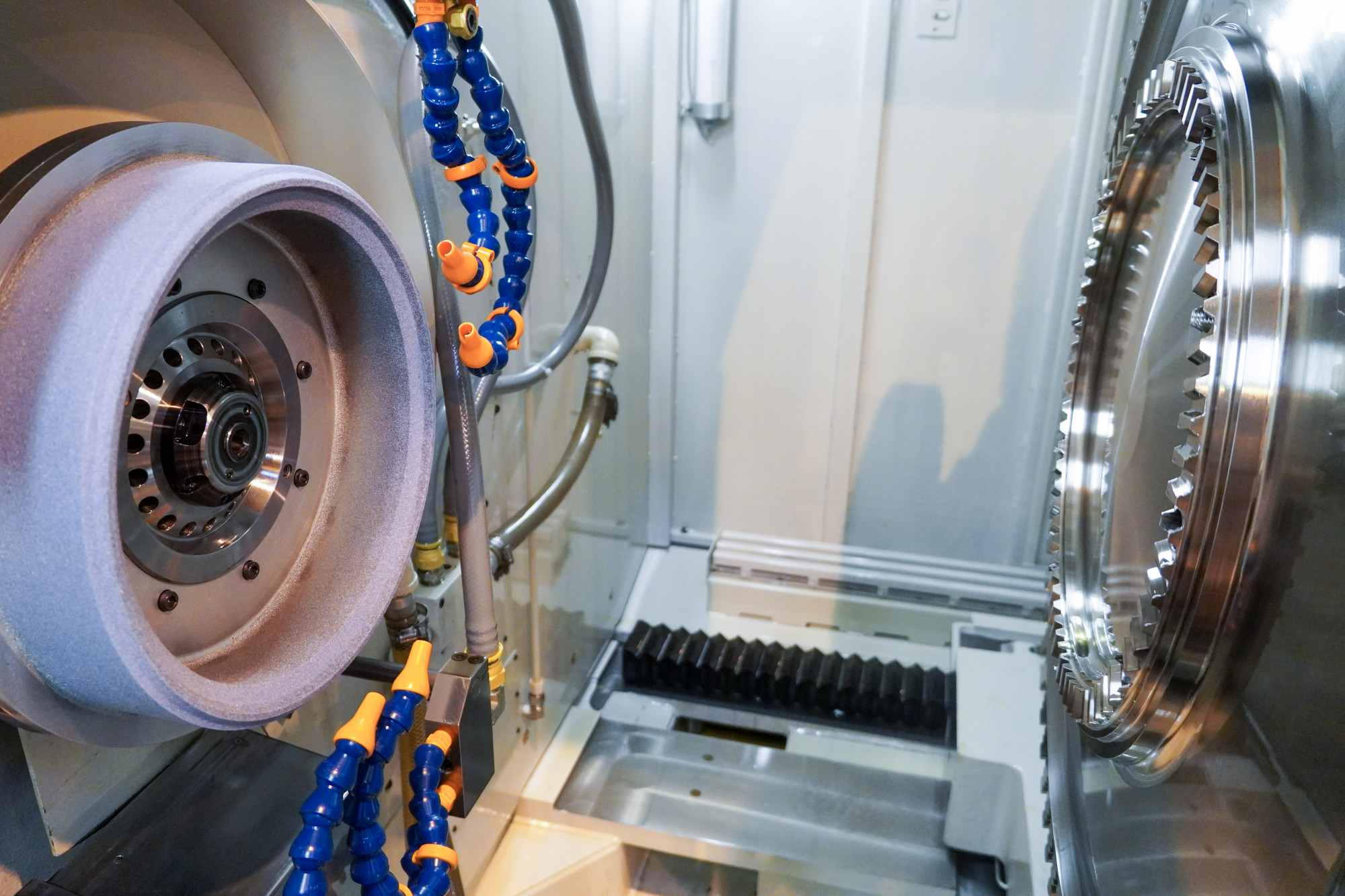

TOOLING

To achieve the highest level of productivity for our manufacturing operations, Metalex has invested in our Tooling and Cutter Grind Area of Expertise, keeping us at the leading edge of cutting tool technology. From selecting carbide grades and coatings to designing complete sets of custom tooling for critical applications, our toolmaking team works closely with our programmers, machinists and outside suppliers to identify opportunities for process optimization while also meeting and exceeding customer quality requirements.

.jpg)

PROGRAMMING

The Metalex programming team serves as the hands-on technology integrator for manufacturing operations across the company. Through close collaboration with our talented team of 5-axis machinists, tool makers, designers, engineers and inspectors, our programmers generate truly innovative machining strategies using the latest CAM software to develop CNC programs that drive our multi-axis machines with the efficiency and precision needed to successfully produce some of the most complex prototypes and production components for the aerospace, space, energy and consumer products industries.

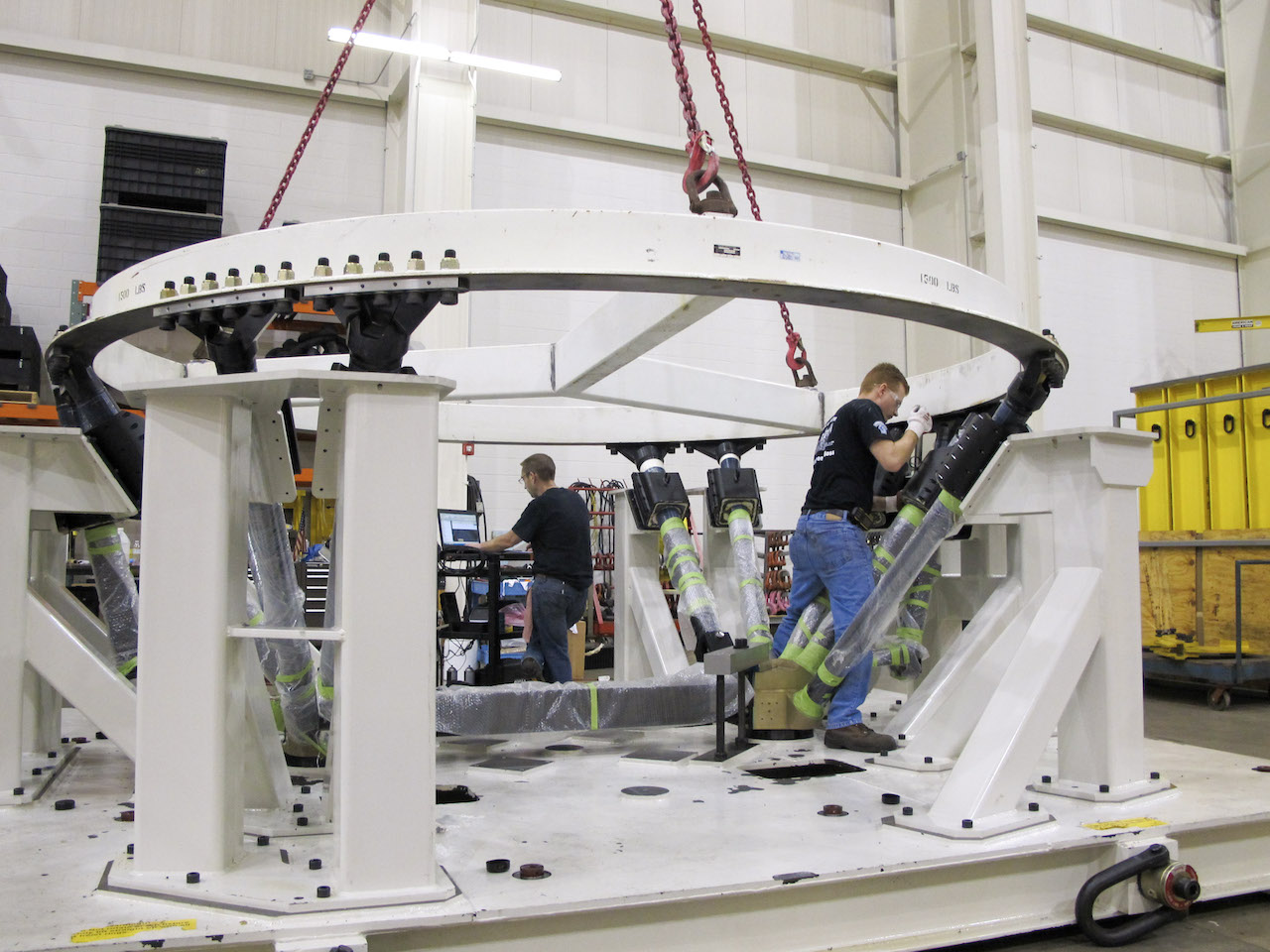

PROJECT MANAGEMENT

The key to ensuring your most complex and challenging projects are a success, is integrated engineering and project management. Working in collaboration with leading engineers, scientists and researchers, Metalex has developed decades of technical project management experience through our hands-on work in high-tech manufacturing, consumer product development, major energy projects and aerospace prototyping.

QUALITY AND CERTIFICATIONS

On difficult parts and assemblies, Metalex team members from our programming, engineering and quality departments work as a team during the start-up, development and prove-out stages of the manufacturing process to ensure we deliver each customer's project to their exact quality specifications and requirements.

MISSION-CRITICAL RAPID RESPONSE

As a full-service machine shop, the Metalex Prototype & Critical Service Center supports clients who require 24/7 response for alterations, repairs and replacement parts. This technology center has the latest 5-axis milling, turning, grinding and welding equipment operated by an extremely talented team of machinists, which allows us to serve a customer base that requires difficult parts with short delivery times, especially mission-critical prototype development parts and projects.

-2.jpg)

ACTIVITY BASED COSTING

A Culture of Activity Based Costing from the Beginning

Since we opened our doors, Metalex has used Activity Based Costing to ensure we are an efficient, cost-conscious and accountable company, this is part of our company culture and DNA. By continuously using actual performance data as a tool to identify best practices, benchmark performance and opportunities for improvement, Metalex is committed to ensuring our customers receive excellent quality at the best possible value.

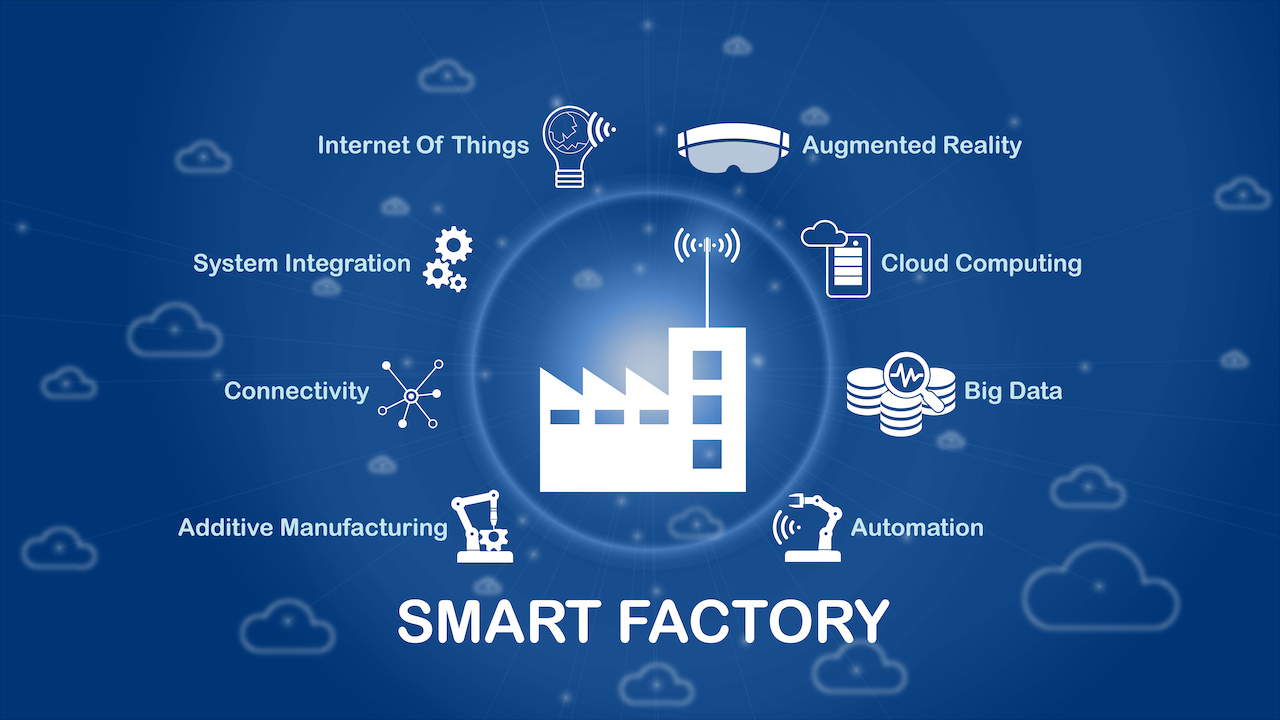

SMART FACTORY - INDUSTRY 4.0 (IIoT)

At Metalex, we emphasize a culture of continuous improvement, transparency, accountability and openness, which is why implementing industry 4.0 has been such a natural evolution that has been readily adopted by our workforce at every level of our organization to help us work smarter to ensure we meet our customer's needs.

.jpeg)

.jpg)