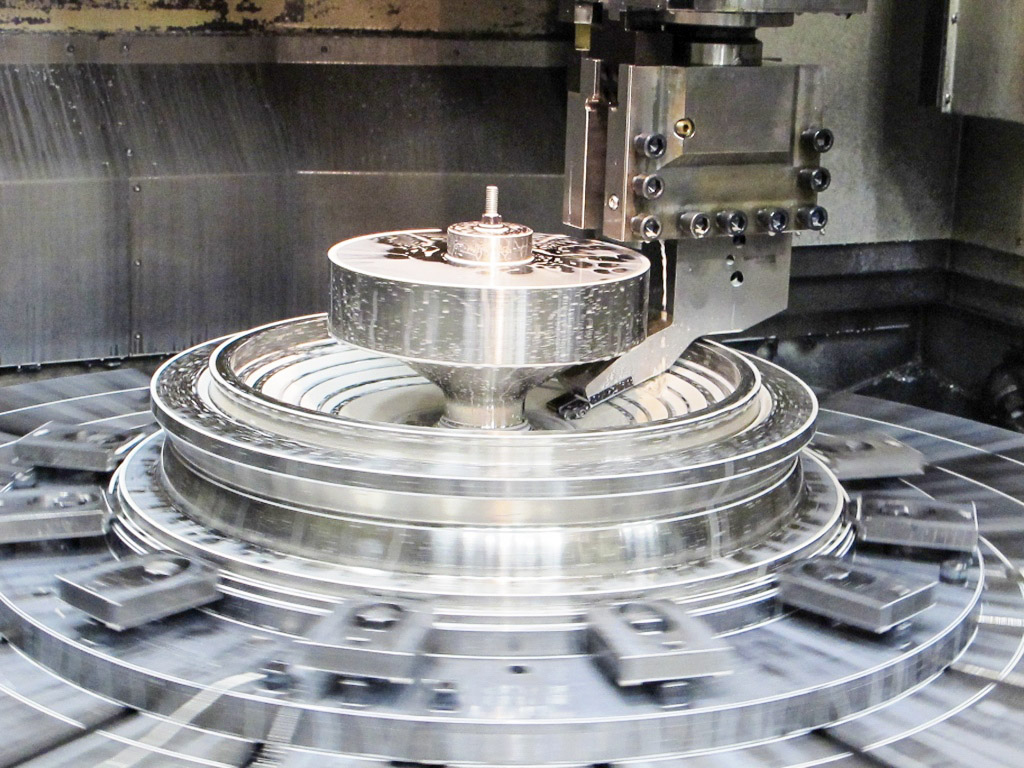

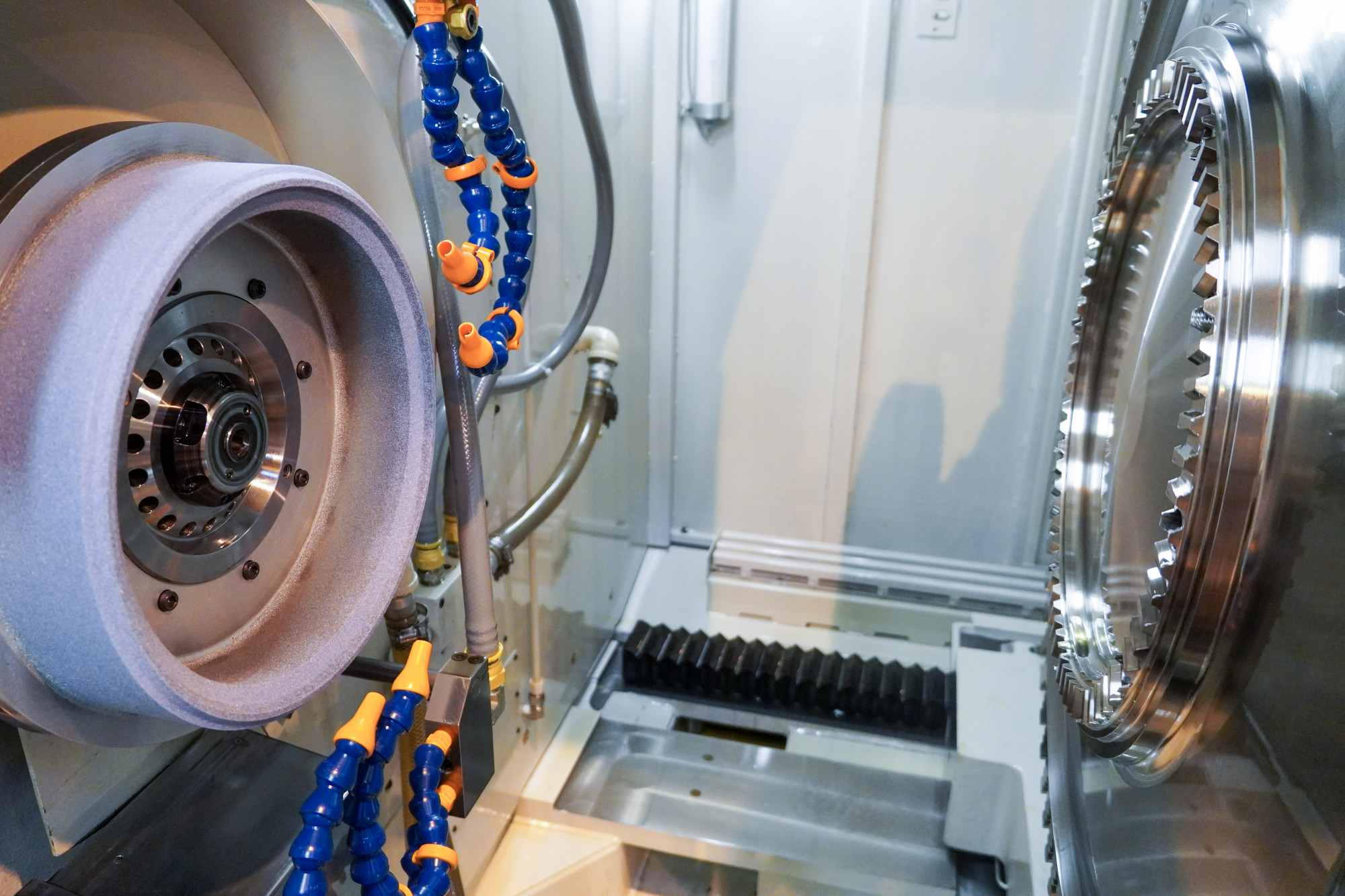

Metalex manufactured the second-generation improved version of the SNS Inner Reflector Plug for the Target Module System. This assembly is a critical component for Spallation Neutron Source Operations at the Oak Ridge National Laboratory. This complex assembly is up to 53 inches in diameter and 17.5 feet long and weighs 65,000 pounds.

The lower Inner Reflector Plug is the most complex section of the assembly. It contains the openings for the target module, the proton beam, and the neutron pulses. Most of the components are made of aluminum and stainless steel. The critical areas of the lower IRP are cooled with liquid hydrogen piped through vacuum jacketed cryogenic lines made of Invar26. Remaining areas are cooled by water moving through a complex maze of interconnected channels. The neutron reflectors are made of beryllium, and the features that eliminate the unwanted neutrons are made of cadmium and gadolinium. There are three U2 Code stamped pressure vessels called moderators in this lower IRP section that Metalex must code stamp prior to completion of the IRP assembly.

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)